Microvial Flow Through Interface

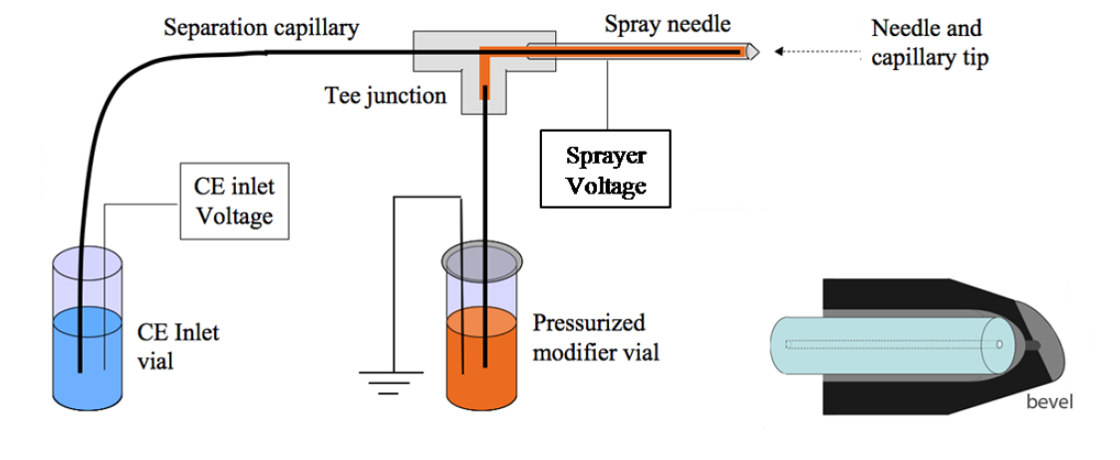

In an analogous way as in the original co-axial sheath-liquid CE-MS interface work by the group of Richard Smith [1], the group of David Chen reported an interface with a metal spray needle and a co-axially delivered modifier [2, 3]. In contrast to Smith, these authors sprayed from a 22’ gauge steel needle with optimized exit geometry. The CE separation capillary is moved forward in this needle until it stops after which it is pulled back minimally to allow a hydraulic liquid connection with the BGE in the separation capillary.

Microvial Flow Through CE-MS IF according to Chen et al.

In the set-up in the figure above, the ESI voltage is established at the spray needle while the MS entrance is at the ground. Careful and safe control of the magnitude and direction of the electrical fields and of the CE and ESI currents is required. Vice versa, in case an Agilent or Bruker MS system is used, the additional ESI-HV power supply is not needed (see pages on co-axial sheath flow IF).

The modifier solvent used typically consists of aqueous alcohols with 0.1% acetic acid and is delivered at sub µL/min flow rates. Apart from providing a wet electrical connection, the modifier solvent flow helps to hydrodynamically focus the BGE and sample constituents coming out of the separation capillary.

This design allows the usage of standard CE capillaries (365 µm o.d. x 50 µm i.d.) providing stability and ease of use of the interface. This interface is now being commercialized by CMP Scientific (EMASS-I, http://cmpscientific.com/index.html).

Recently, Lindenburg et al. compared the flow-through microvial interface with the conventional co-axial sheath-liquid interface for the profiling of cationic metabolites [4]. This study revealed a slightly better sense of the flow-through microvial CE-MS interface. Sensitivity was dependent on the flow rate of the modifier solvent. The authors also reported that this interface does not tolerate high CE currents as the formation of electrolysis gases may accumulate in the spray needle and will hamper electrical contact.

![]()

[1] Smith R.D., Barinaga C.J., Udseth H.R. (1988) Anal Chem 60 1948-1952

[2] Maxwell E.J., Zhong X., Zhang H., van Zeijl N., Chen D.D.Y. (2010) Electrophoresis 31 1130-1137

[3] Zhong X, Maxwell E.J., Ratnayake C, Mack S, Chen D.D.Y. (2011) Anal Chem 83 8748-8755

[4] Lindenburg P.W., Ramautar R, Jayo R.G., Chen D.D.Y, Hankemeier T. (2014) Electrophoresis 35 1308-1314